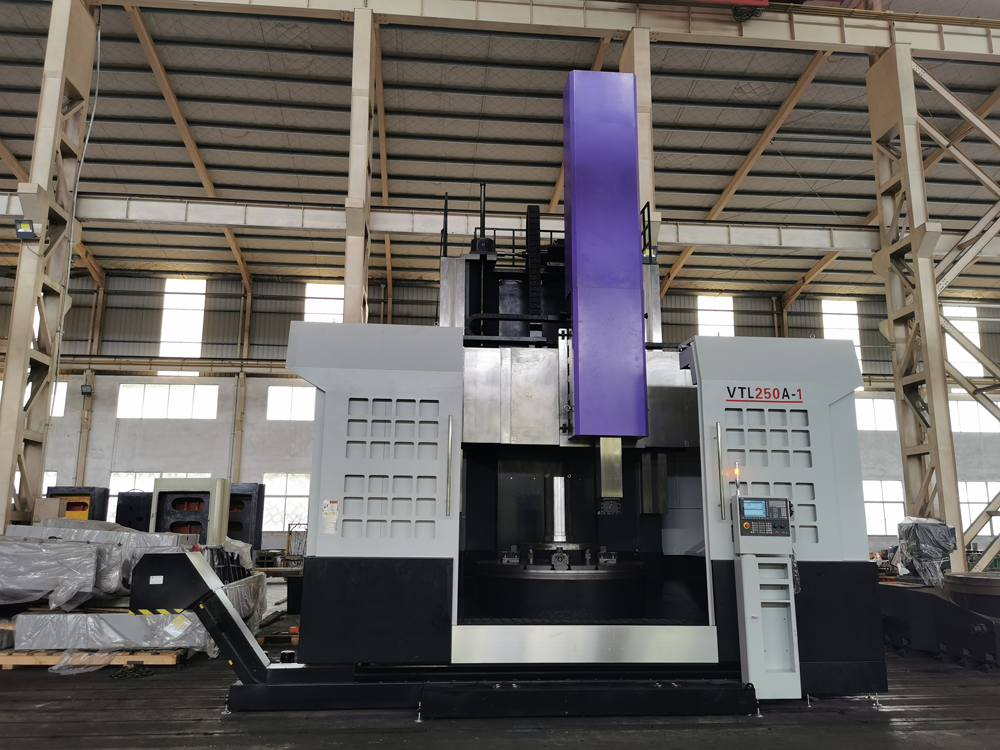

Nui-nuiʻO nā lathe kū pololei CNCnā mīkini nui, i hoʻohana ʻia e hana i nā mea hana nui a kaumaha me nā ana radial nui a me nā ana axial liʻiliʻi liʻiliʻi, a me nā ʻano paʻakikī. No ka laʻana, hiki ke hana ʻia ka cylindrical surface, end surface, conical surface, cylindrical hole, conical hole o nā discs like ʻole, huila a me nā ʻāpana hana me ke kōkua o nā mea hana hou no ka threading, spherical surface, profiling, milling and grinding.

ʻO ka manawa kōkua o ka nui-nuiCNC VTL Mīkinipōkole loa. Hiki iā ia ke hoʻopau i nā maʻiʻo hana āpau i hoʻokahi clamping. E ho'āʻo e koho i ka mea hāmama me ka rigidity kiʻekiʻe, ʻaʻole hiki ke hoʻopilikia i ke ala mea hana, a hiki ke hoʻopau i ka hana ʻana o ka mea hana i loko o ke ʻano o ka hahau spindle. Ma ke ʻano he mīkini ʻenehana nui loa, e ʻike ʻia nā ʻano alarm like ʻole ma hope o kahi manawa o ka hoʻohana. He hemahema ʻōnaehana kekahi, he mau hoʻonohonoho ʻokoʻa kūpono ʻole kekahi, a he mau hemahema kekahi. ʻO nā alarm alarm kekahi o lākou.

Ke hiki mai ia ʻano, e nānā mua i ka peʻahi kūloko. Inā ʻaʻole e huli, e wehe a ʻike. Inā haumia loa, holoi maʻemaʻe me ka waiʻona a i ʻole ka ʻaila ma mua o ke kau ʻana. Inā he alarm, pono ʻoe e hoʻololi i ka amplifier servo. Hōʻike ʻia ʻo HC. ʻO ka alarm o kēia manawa, ʻo ka mea nui e ʻike i ka manawa maʻamau ma ka ʻaoʻao DC, e nānā mua i nā ʻāpana servo, a laila wehe i ka laina mana kaʻa. I loko o ka manawa, aia kahi alarm e hoʻololi i ka amplifier servo. ʻAʻohe pumehana. E hoʻololi i ke kaʻa a me ka laina mana me nā axis ʻē aʻe e hoʻoholo ai inā ʻo ia ka moto a i ʻole ka laina mana. Pilikia: Inā ʻike ʻia ʻo J ma ka hōʻike, pili ia i ka pilikia PC. E nānā inā pololei ka motherboard, ka papa hoʻololi hoʻololi a me ka mea hoʻokele PCRAM, hoʻololi a hoʻopau a hoʻoholo ʻia ke kumu, a laila hoʻoponopono i ka pilikia.

Ke hiki mai ia ʻano, e nānā mua i ka peʻahi kūloko. Inā ʻaʻole e huli, e wehe a ʻike. Inā haumia loa, holoi maʻemaʻe me ka waiʻona a i ʻole ka ʻaila ma mua o ke kau ʻana. Inā he alarm, pono ʻoe e hoʻololi i ka amplifier servo. Hōʻike ʻia ʻo HC. ʻO ka alarm o kēia manawa, ʻo ka mea nui e ʻike i ka manawa maʻamau ma ka ʻaoʻao DC, e nānā mua i nā ʻāpana servo, a laila wehe i ka laina mana kaʻa. I loko o ka manawa, aia kahi alarm e hoʻololi i ka amplifier servo. ʻAʻohe pumehana. E hoʻololi i ke kaʻa a me ka laina mana me nā axis ʻē aʻe e hoʻoholo ai inā ʻo ia ka moto a i ʻole ka laina mana. Pilikia: Inā ʻike ʻia ʻo J ma ka hōʻike, pili ia i ka pilikia PC. E nānā inā pololei ka motherboard, ka papa hoʻololi hoʻololi a me ka mea hoʻokele PCRAM, hoʻololi a hoʻopau a hoʻoholo ʻia ke kumu, a laila hoʻoponopono i ka pilikia.

He aha nā mea e pono ai ka nānā ʻana i ka mālama ʻana i ka CNC nuiVTL Mīkini?

1. Ma hope o ka hoʻomaka ʻana i ka mīkini nui i kēlā me kēia manawa, ʻaʻole hiki ke hoʻomaka koke ka spindle. Ma hope wale nō o ka hana maʻamau o ka pauma lubrication a hele mai ka puka ʻaila me ka ʻaila, hiki ke hoʻomaka ka spindle e hana i ka mīkini hana.

2. Hiki ke hoʻohana wale ʻia ka wili i ka wā e hoʻohuli ai i nā kaula e hōʻoia i kona pololei a me ke ola.

3. E mālama i loko a me waho o kamea hana mīkinino ka maʻemaʻe, ua paʻa nā ʻāpana mīkini, ʻaʻole aila nā ʻuala a me nā lāʻau i poni ʻia, a maʻemaʻe a paʻa nā ʻaoʻao alakaʻi.

4. E hana i ka hana lubrication o kēlā me kēia wahi lubrication e like me nā koi i kuhikuhi ʻia (e ʻike i nā kuhikuhi lepili o ka ʻōnaehana lubrication mea mīkini no nā kikoʻī).

5. E nānā mau a hoʻoponopono i ka paʻa o ke kāʻei V o kaʻO ka lathe kūpaʻa CNC.

6. E hoʻolohe i ka nānā ʻana i ke kūlana hana o ka ʻaila ʻaila e hōʻoia i ka nui o ka pahu poʻo a me ka pahu hānai. ʻAʻole e emi iho ka ʻaila lubricating i loko o kēlā me kēia pahu ma mua o ke kikowaena o kēlā me kēia maʻamau o ka aila, inā ʻaʻole e pōʻino ka mea mīkini ma muli o ka lubrication maikaʻi ʻole.

7. E hoʻomaʻemaʻe i ka ʻaila kānana keleawe o ka ʻaila kānana i loko o ka ʻaila ʻaila o ka pahu moe i kēlā me kēia pule e hōʻoia i ka maʻemaʻe o ka ʻaila lubricating.

8. I ka wā e kaʻawili ai ka milo i ka wikiwiki, ʻaʻole pono ʻoe e huki i ka lima hoʻololi.

Ka manawa hoʻouna: Nov-24-2021